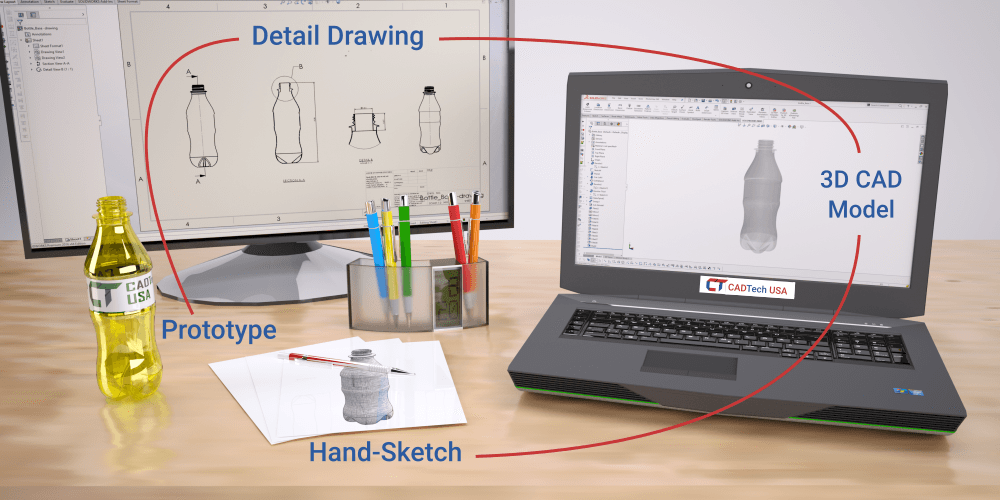

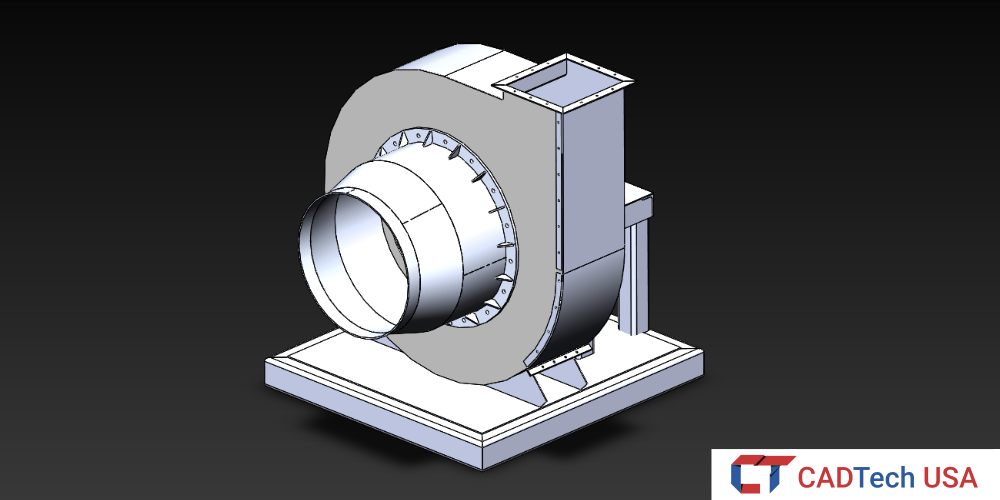

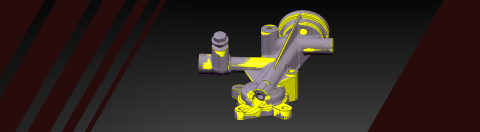

Mechanical Design

We design for real-world manufacturing.

INDUSTRIAL PRODUCT

DESIGN

Industrial Product Design

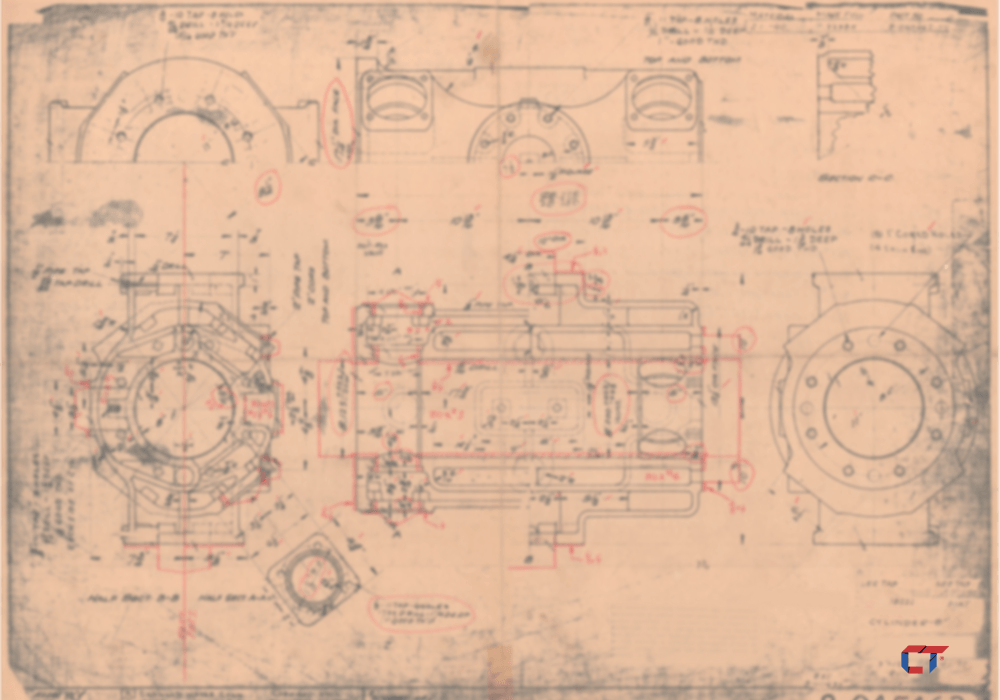

Legacy CAD Conversion

Drawing

Drawing

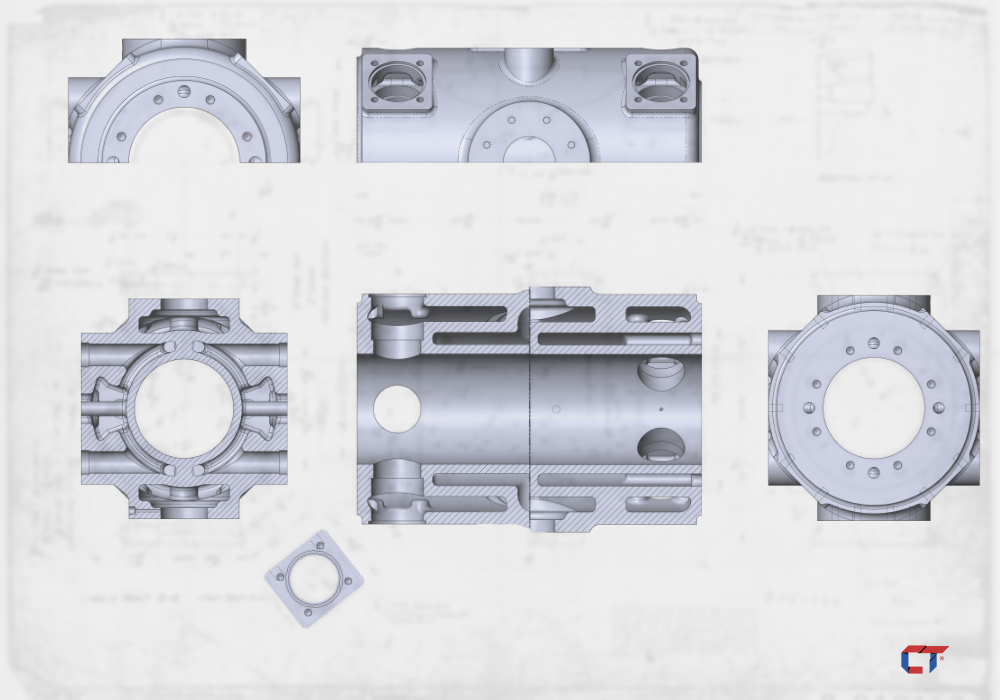

Modified 3D Model

Modified 3D Model

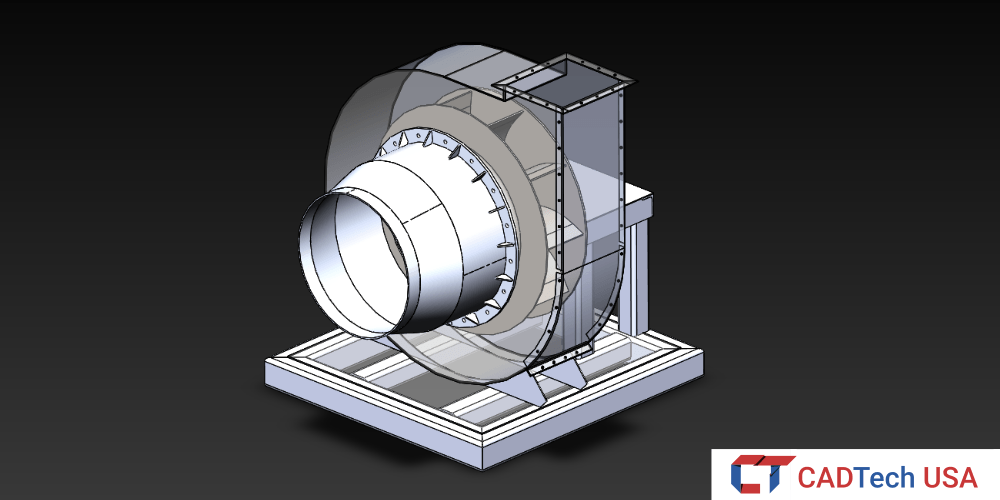

Sheetmetal and Weldments

Weldments

Weldments

Sheetmetal

Sheetmetal

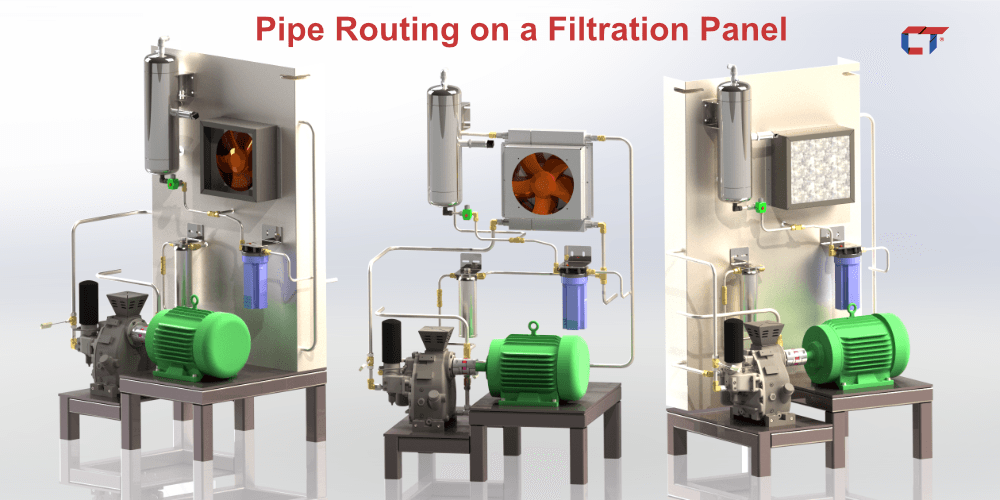

Pipe Routing and Fabrication

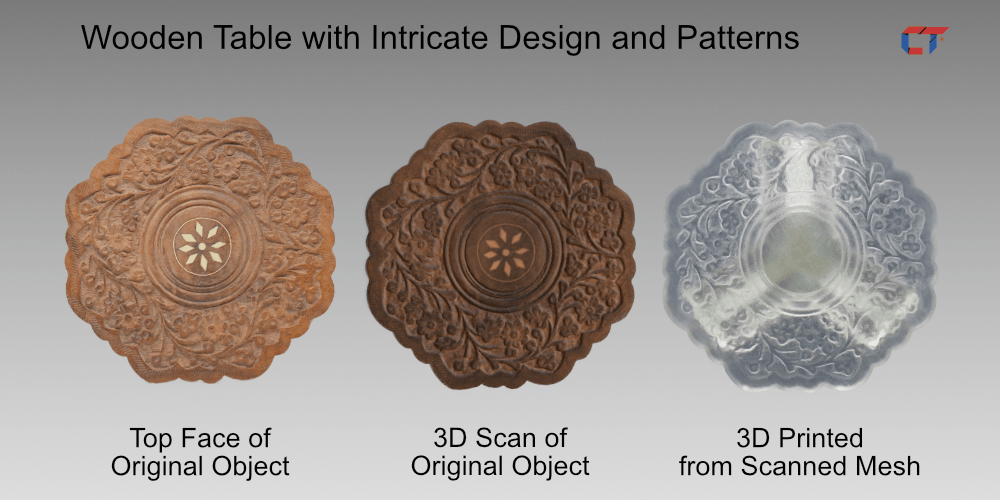

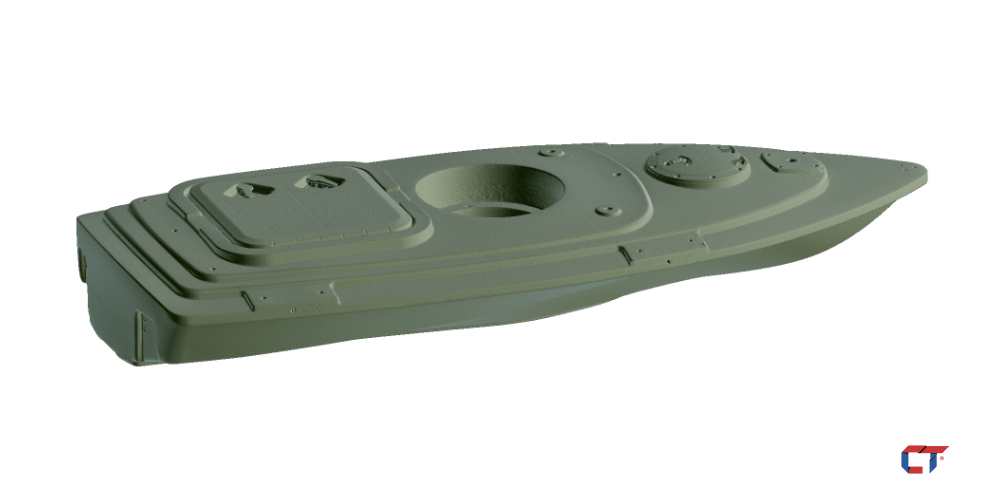

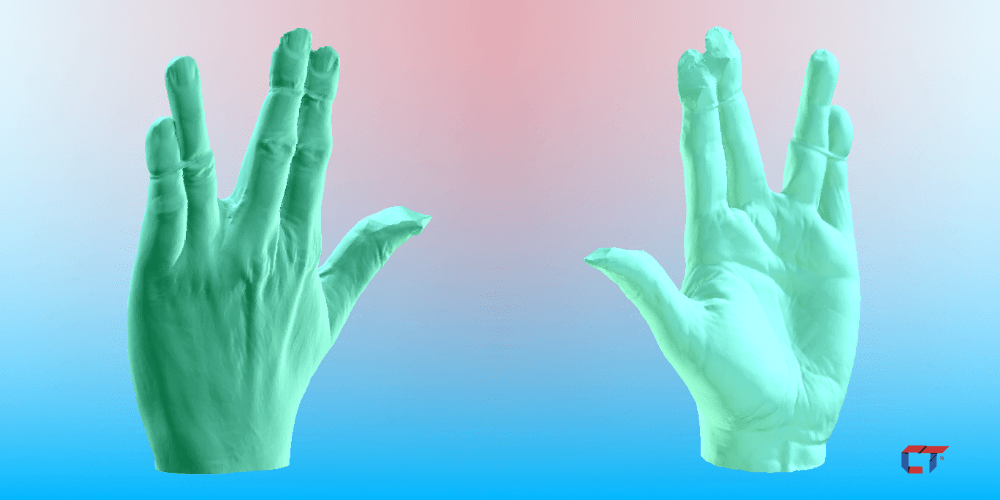

3D Scanning

We capture reality for digital innovation.

DIGITIZATION FOR

MANUFACTURING

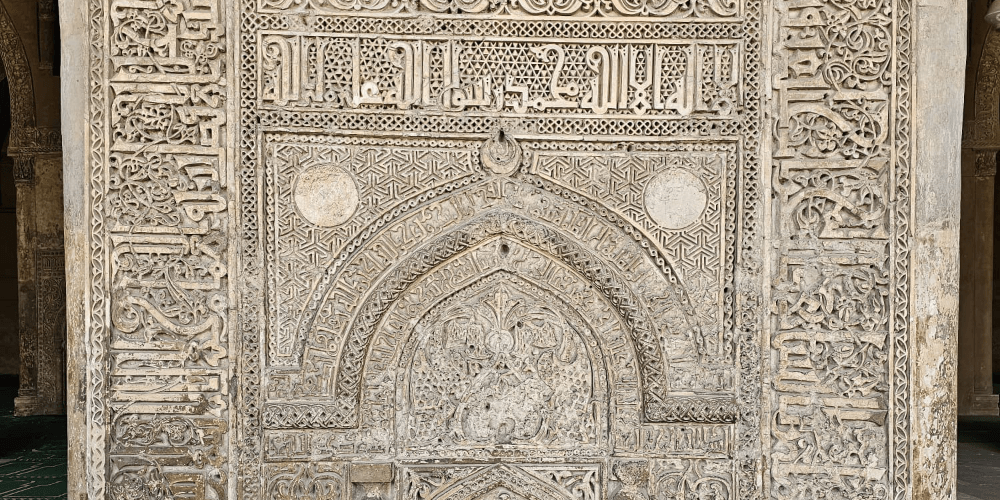

HERITAGE AND DIGITAL

PRESERVATION

Digitization for Manufacturing

Heritage and Digital Preservation

Digital Twin Creation

Research and Analysis

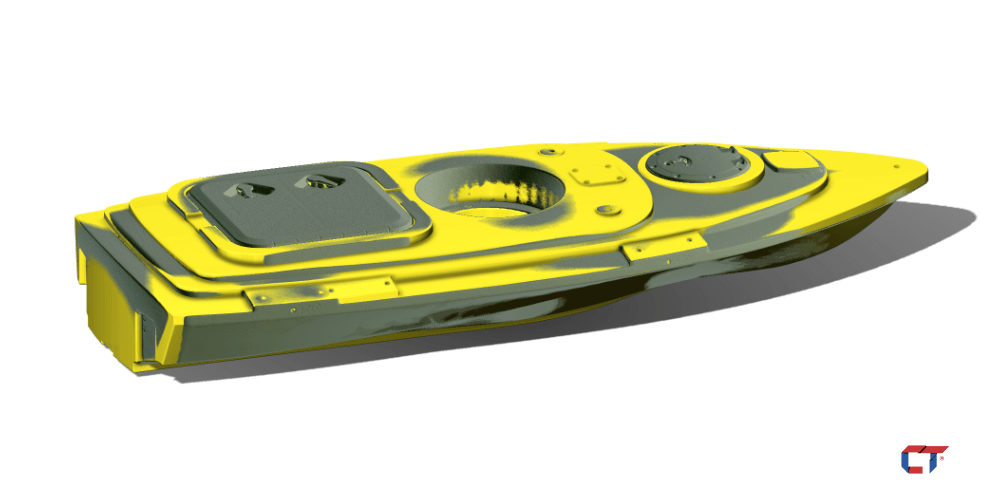

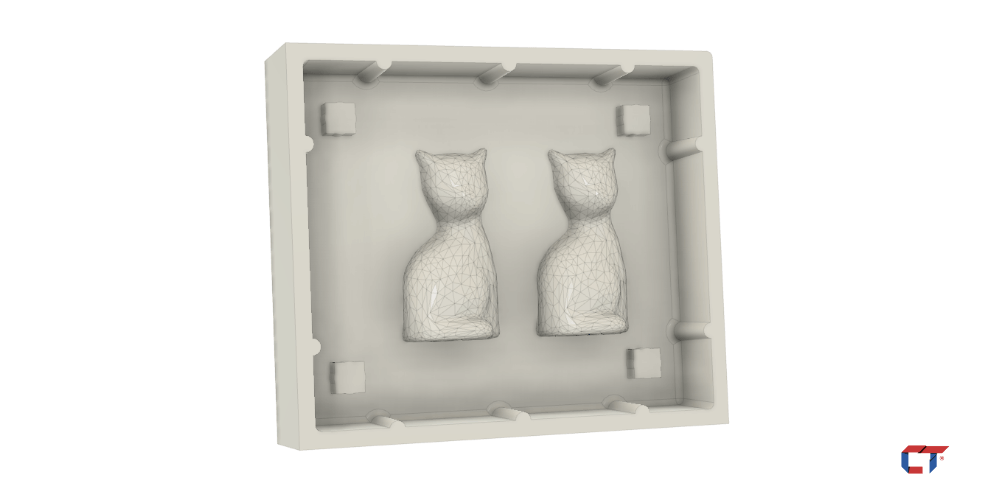

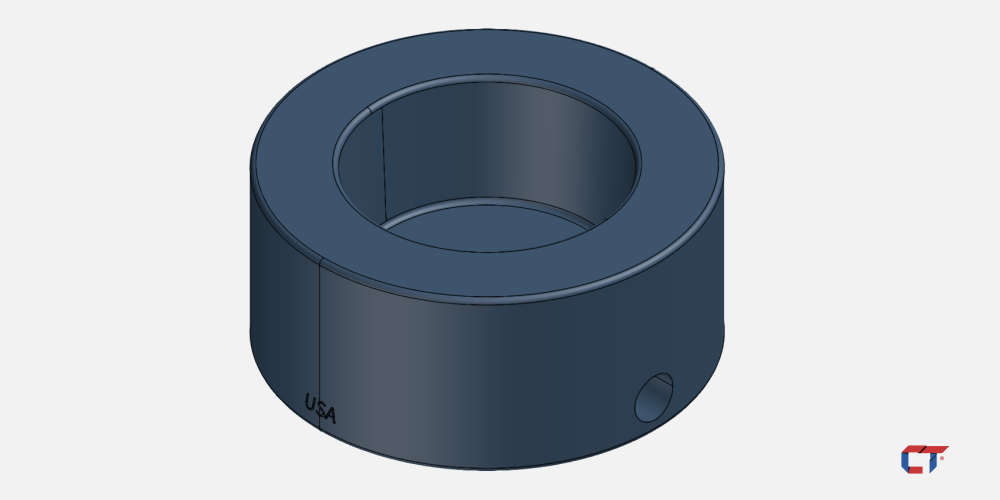

Scan-to-CAD

We transform scanned data into 3D CAD.

LEGACY SYSTEMS &

AFTERMARKET PARTS

Legacy Systems & Aftermarket Parts

Modifying Existing Systems

Modified CAD

Modified CAD Scanned

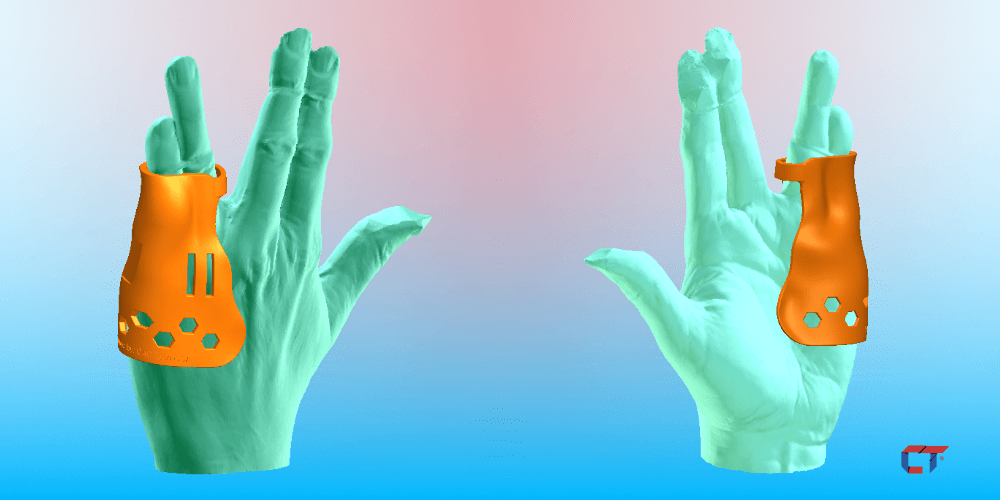

ScannedBioengineering Applications

CAD

CAD Scanned

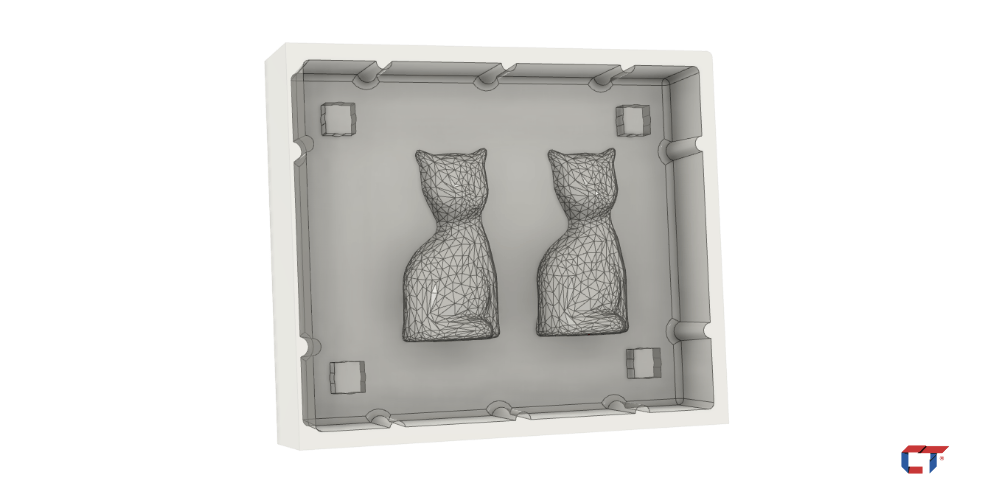

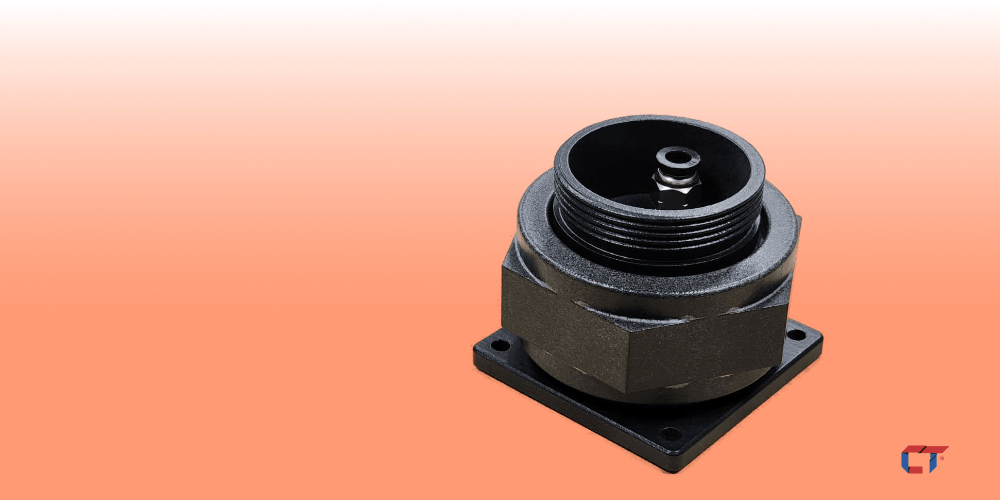

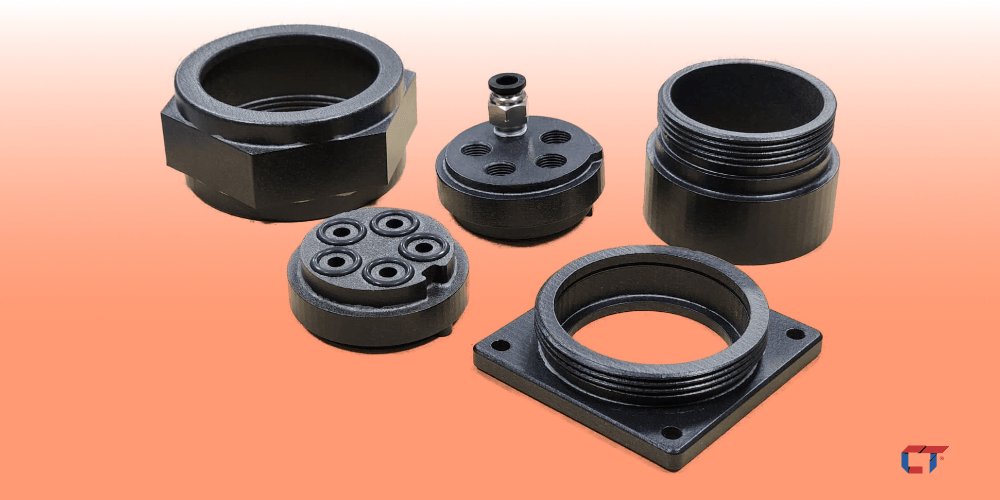

ScannedPackaging and Mold Design

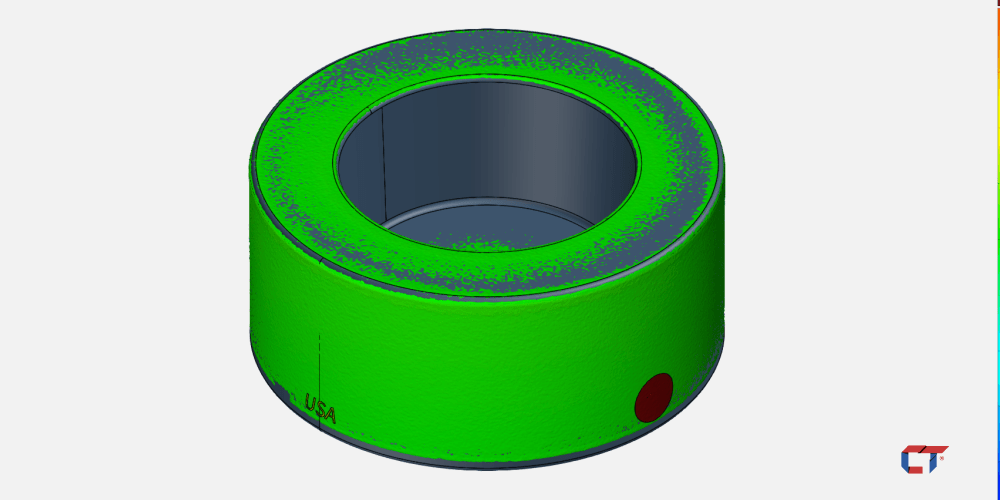

Mold for

Mold for Plastic

PlasticScan-to-Inspection

We validate reality against design intent.

First Article Inspection (FAI)

CAD Model

CAD Model

Mesh Overlay

Mesh Overlay

Batch Inspection and Trend Analysis

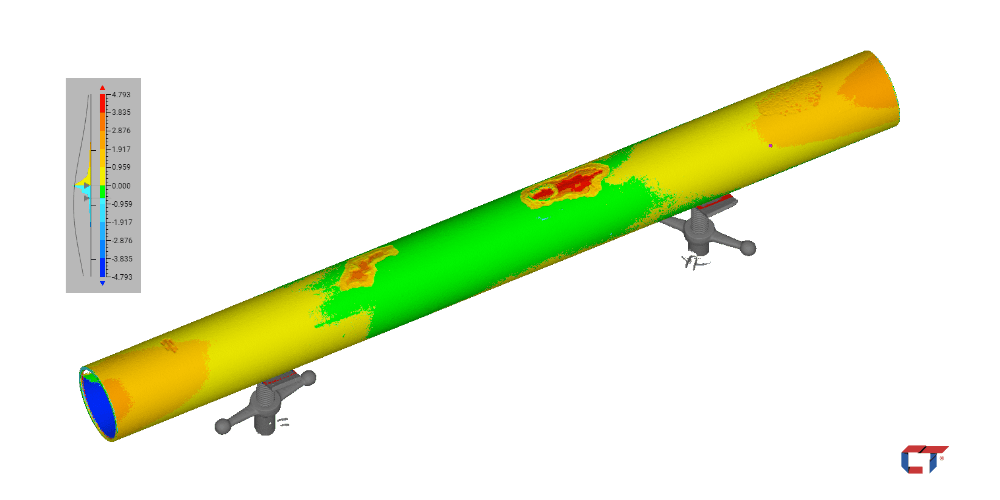

Damage Detection and Reporting

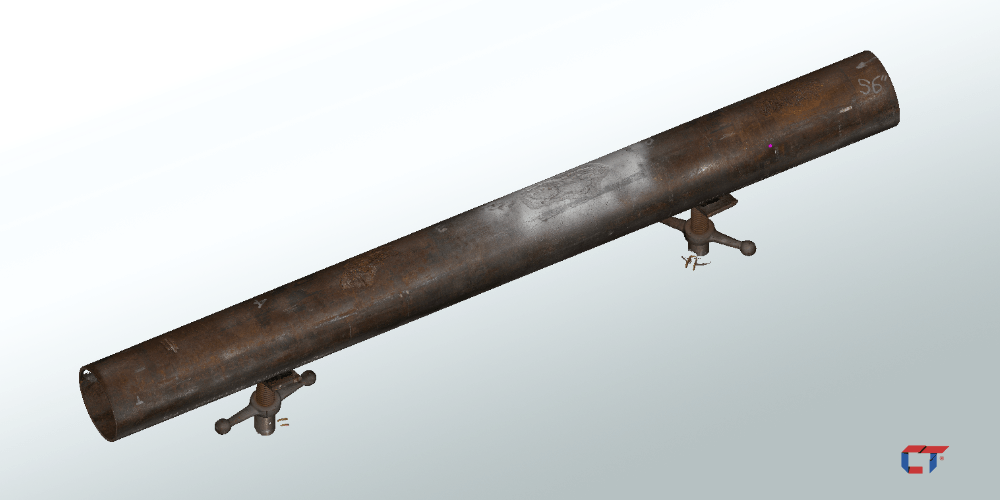

3D Scanned Model

3D Scanned Model

Damage Overlay

Damage Overlay

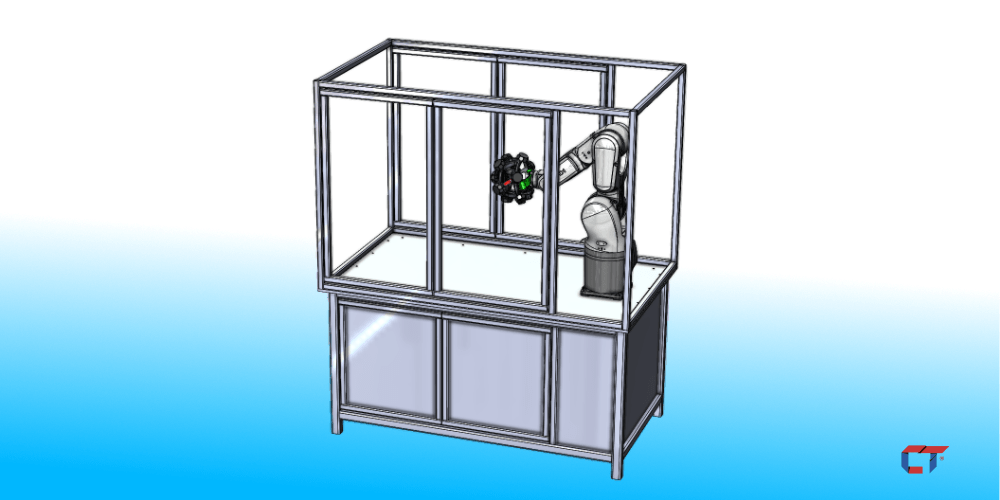

Automated Solutions

Add-on Services

Finite Element Analysis

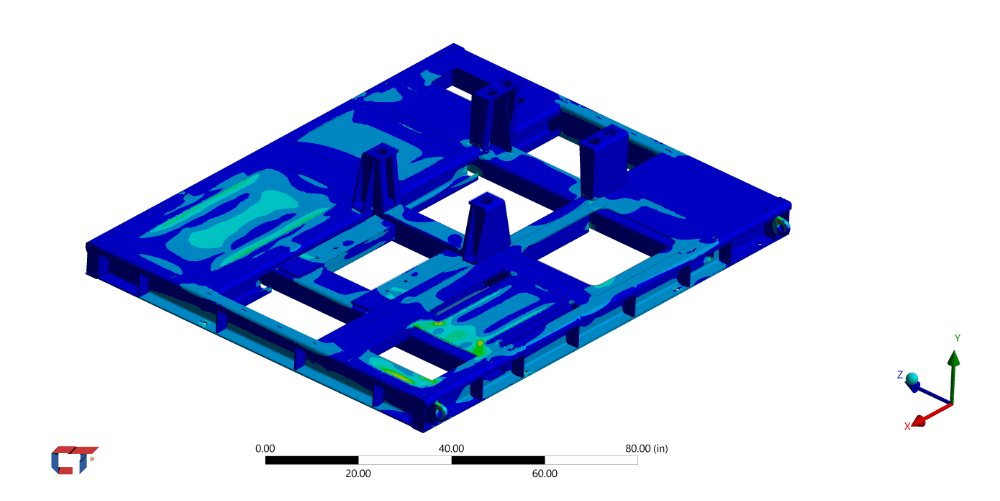

Stress Plot

Stress Plot

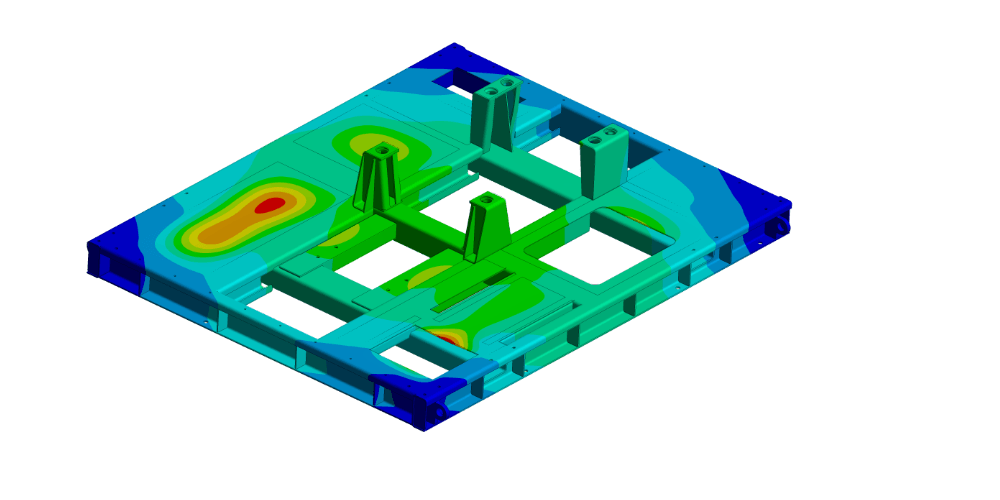

Displacement Plot

Displacement Plot

3D Printing

Fast-Prototyping

Manufacturing and Procurement

Products

Our Partners

Our Customers & Trusted Partners

Certifications

TWIC Access Approved

Fluid Power Specialist