Flexibility meets precision

Scan Anything, Anytime, Anywhere

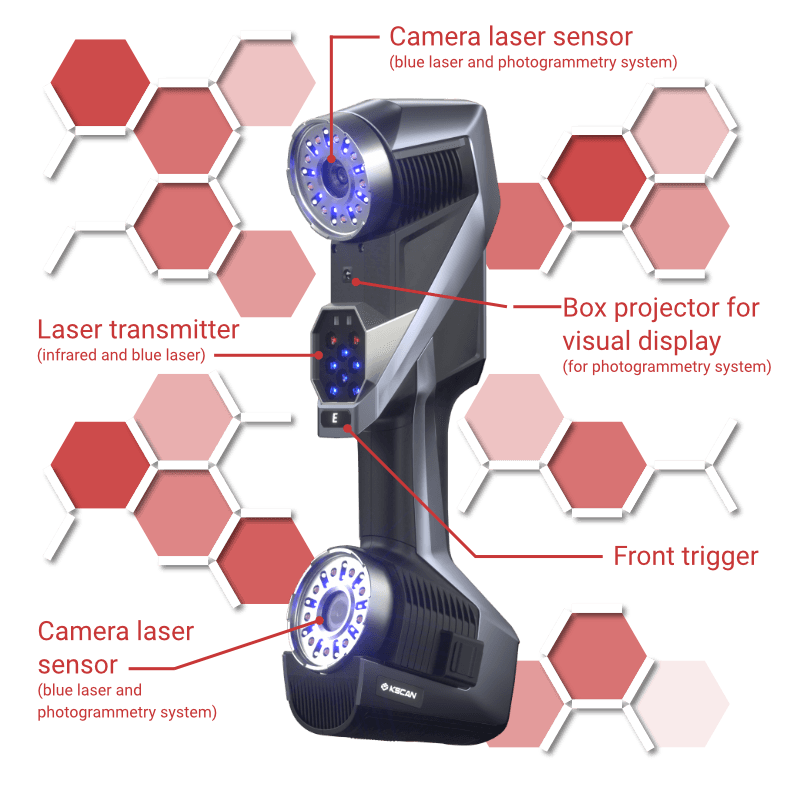

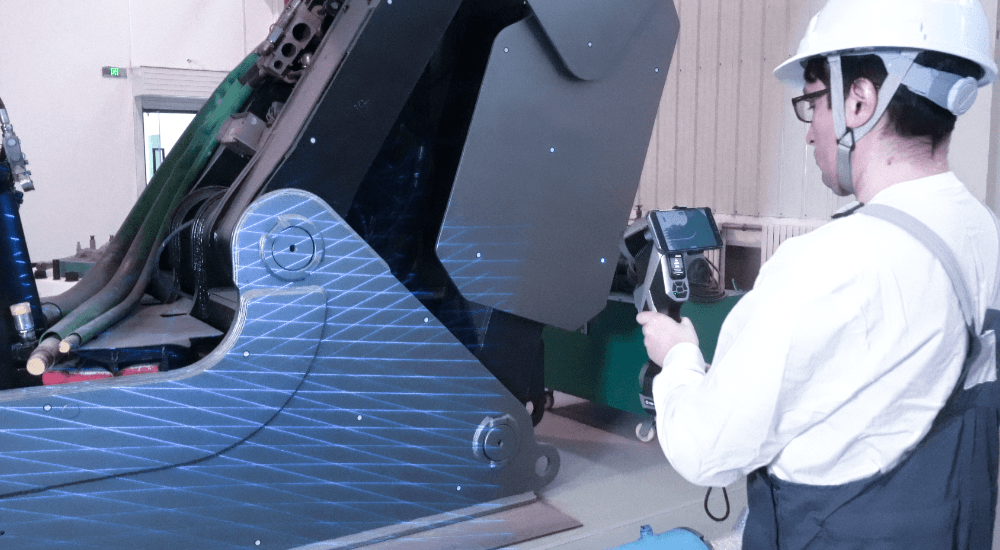

The KSCAN-E is robust, flexible and versatile 3D scanner, ideal for scanning small to large objects wherever you are. With multiple laser technologies and modes, the KSCAN-E allows for rapid data capture without compromising accuracy. Moreover, KSCAN-E is capable of 3D scanning various surfaces to capture precise 3D data, and it performs well even in 3D scanning reflective and black surfaces.

Additionally, the KSCAN-E is a fully mobile and cable-free system. It is perfect for 3D scanning large-scale objects, operating in remote areas with no power supply, or working in harsh conditions.

Uncompromising Accuracy and Efficiency

The KSCAN-E delivers exceptional accuracy of 0.020 mm at remarkable speeds for unparalleled industrial reliability. Its innovative quad-cross technology—4x27 blue laser lines—accelerates data capture to an incredible 8.29 million measurements/s, drastically reducing inspection time.

Volumetric accuracy can be further enhanced by pairing it with the L15 photogrammetry system or a precise scale bar, guaranteeing confidence in the most demanding applications.

Superior Resolution for Flawless Inspection

Capture Minute Details with Exceptional Clarity

Equipped with 17 parallel blue laser lines and high-performance cameras, this scanner achieves an ultra-fine 0.010 mm resolution. Powered by DefinSight real-time meshing, it instantly renders even the most subtle part features—like precise gaps and slots—with absolute accuracy, ensuring no defect goes undetected.

Large Parts & High Efficiency

The adaptive photogrammetry and wide-area infrared scanning modes deliver high accuracy for massive parts. With 38 laser lines, a 1.5 m working distance and a large scanning area, this solution ensures efficient and precise measurement of complex, large-scale components.

Medium Sized Parts & Fine Details

Utilizes Hyper-fine scanning mode (parallel blue lasers) to meticulously scan and capture the most intricate part details with exceptional precision. This ensures flawless quality control for complex components like injection molds and finely machined gear teeth.

Hole & Edge Inspection

Advanced laser and grayscale recognition technology in ensures high-precision inspection of various holes, slots, and complex part edges for accurately measuring stamped and irregular parts.

Scanning Complex Grooves

Effortlessly capture precise measurements of hard-to-reach internal features like engine cylinders and grooves on casted parts with the specialized deep-hole scanning mode.

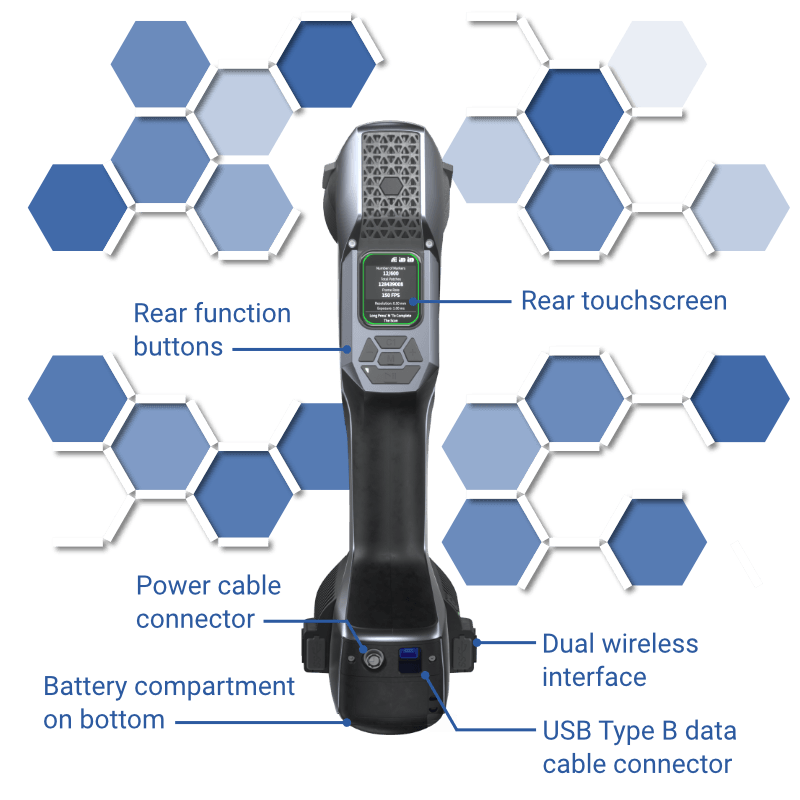

Real-time phone screen viewing and touchscreen interface

For the ultimate wireless 3D scanning experience

Complete the KSCAN-E’s wireless system with the included optional smartphone holder to attach your smartphone to the KSCAN-E and directly view what you are scanning for a truly seamless 3D scanning experience. Use the built-in full-color touchscreen for real-time harware and software updates. Coupled with the customizable buttons, the KSCAN-E is the ultimate wireless blue laser scanner in the industry.

Industrial Grade Protection

Compact and secure storage

All SCANOLOGY products are packaged in industrial grade cases to assure that all components are stored securely and to make sure that no damage is caused during transportation.

In addition, the smart design of the protective case ensures that all components needed for the operation of the system can be accessed quickly.

Metrology-grade NDT Measuring

In addition to its built-in photogrammetry system, the KSCAN-E 3D scanner can be coupled with the MSCAN-L15 photogrammetry system, to further the overall volumetric accuracy to an industry leading 0.015 mm + 0.012 mm/m (0.0006 in + 0.00014 in/ft). This technology is pivotal in driving ultra-high precision non-destructive testing (NDT) for a diverse range of industries.

The KSCAN-E has four different scanning modes. The first three modes utilize the blue lasers, while the fourth uses infrared lasers.

The difference between the three blue laser scanning modes is the number and configuration of the lasers. Basically, the higher laser count equates to faster scanning speeds while taking a small dip in accuracy and resolution. However, the scanning modes can be flexibly switched and combined to satisfy different application needs while satisfying the metrology-grade accuracy required for an efficient workflow.

The fourth mode uses infrared lasers to scan large objects the size of a small boat. The infrared laser allows for faster scanning times, in contrast to the blue lasers which are engineered for accuracy.

This unique combination of lasers makes the KSCAN-E a true all-purpose scanner.

The KSCAN-E is a versatile scanner that is able to scan objects the size of a coin up to a small boat. This is made possible due to the unique combination of blue laser + infrared laser technology. The blue laser is used for fine scanning, while the infrared laser makes it possible to scan large objects. Additionally, it also has an in-built photogrammetry system to avoid any loss in volumetric accuracy.

The inclusion of infrared laser and the built-in photogrammetry system makes the KSCAN-E standout from all other 3D scanners in its class. The infrared laser brings to the table the ability to scan large objects the size of a turbine, while the photogrammetry system helps maintain a high volumetric accuracy when scanning those large objects.

The Hole Inspect Mode is used to scan and extract edges of very thin parts like sheetmetal. Most 3D laser scanners have a hard time in accurately scanning edges of thin parts without increasing file sizes exponentially.

The Hole Inspect Mode works by emitting light from two LEDs to calculate the grayscale value of the reflection. This results in very fast and accurate capture of thin edges while maintaining smaller file sizes.

Award-winning, light and compact metrology grade 3D scanner with an ergonomic design

| Scanner Type | Handheld |

| Object Size 🛈 Typical Object Sizes: XS: Coins, Jewelery S: Camera, Pumps M: Engines, Sculptures |

XS, S, M |

| Laser source | Blue |

| Accuracy | Up to 0.020 mm |

| Resolution | Up to 0.025 mm |

| Output Type | 3D mesh |

Intelligent fully wireless optical tracking system for precision 3D scans without targets

| Scanner Type | Wireless, Handheld |

| Object Size 🛈 Typical Object Sizes: S: Camera, Pumps M: Engines, Sculptures L: Small boats, Turbines |

S, M, L |

| Laser source | Blue |

| Accuracy | Up to 0.025 mm |

| Resolution | Up to 0.020 mm |

| Output Type | 3D mesh |

Intelligent optical tracking system for delivering ultra-high precision 3D scans without markers

| Scanner Type | Handheld |

| Object Size 🛈 Typical Object Sizes: M: Engines, Sculptures L: Small boats, Turbines |

M, L |

| Laser source | Blue |

| Accuracy | Up to 0.025 mm |

| Resolution | Up to 0.020 mm |

| Output Type | 3D mesh |

Optical probing system for high-accuracy and flexible measurements

| CMM Type | Wireless, handheld |

| Object Size 🛈 Typical Object Sizes: S: Camera, Pumps M: Engines, Sculptures L: Small boats, Turbines |

S, M, L |

| Volumetric Accuracy | Up to 0.049 mm |

| Measurement Distance | 10 m |

| Part Size Range | 0.1 m to 12 m |

| Output Type | 3D points |

Photogrammetry system tailored to deliver precise geometric measurements of large parts

| CMM Type | Optical, handheld |

| Object Size 🛈 Typical Object Sizes: M: Engines, Sculptures L: Small boats, Turbines |

M, L |

| Volumetric Accuracy | 0.015 mm/m |

| Depth of field | 6.5 m |

| Capture area | Up to 9.4 m x 6.9 m |

| Output Type | 3D points |

Cutting-edge 3D scanner for capturing detailed 3D geometry and rich colors in textures

| Scanner Type | Handheld |

| Object Size 🛈 Typical Object Sizes: S: Camera, Pumps M: Engines, Sculptures |

S, M |

| Laser source | Structured infrared VCSEL |

| Accuracy | Up to 0.1 mm |

| Color reproduction | 24 bit |

| Output Type | 3D mesh + texture |