Metrology-grade accuracy for small parts

For objects up to 20 cm in size

Expect superior data precision with an accuracy down to 5 microns, positioning Micro II as the optimal 3D scanner for advanced reverse engineering and quality inspection of minute parts. Experience crystal-clear quality in every scan!

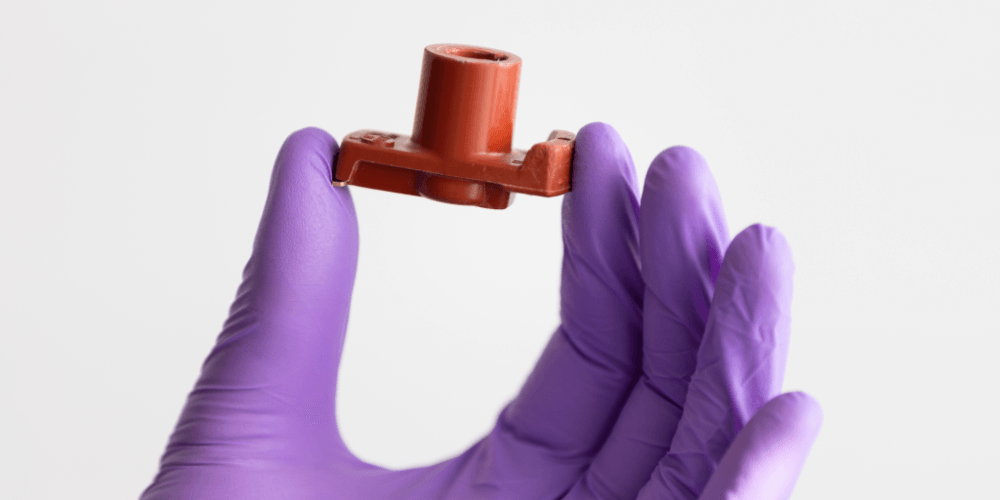

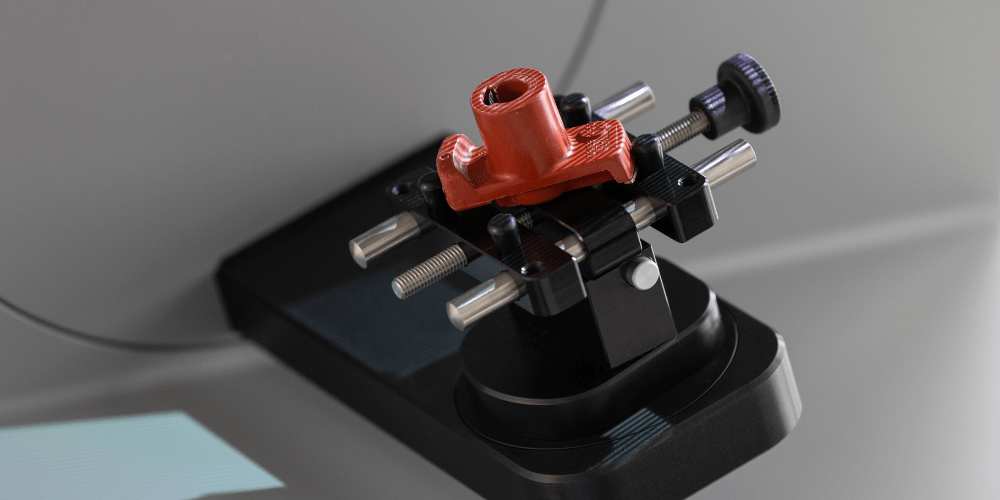

Scan anything you can hold (and under)

Up to 20 × 20 × 15 cm

From small objects that can be held between two fingers to those fitting in the palm of your hand (20 × 20 × 15 cm), Micro II efficiently operates right from your desktop. It requires minimal effort on your part and eliminates the need for any targets during scans.

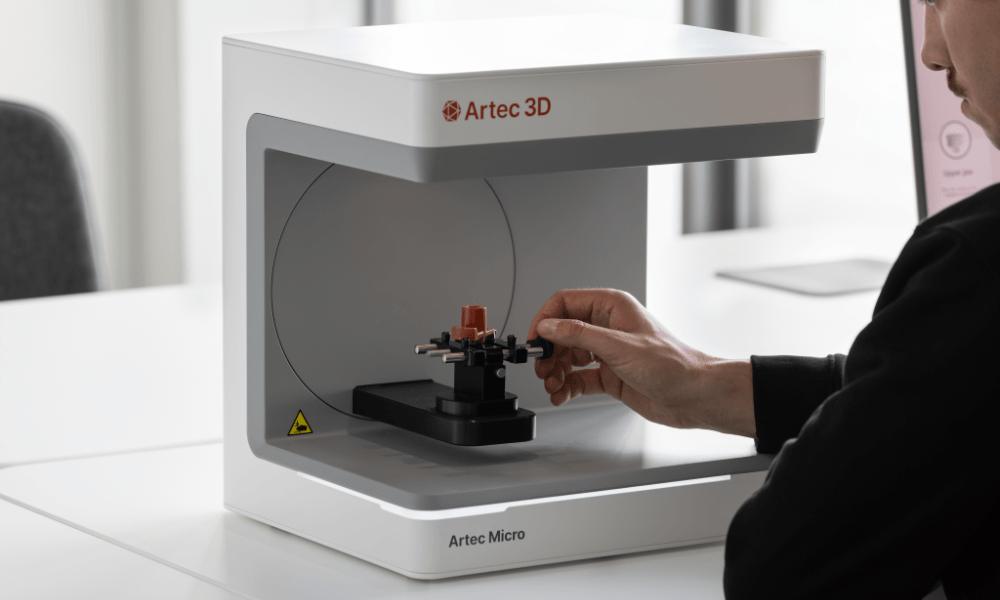

Fast & easy

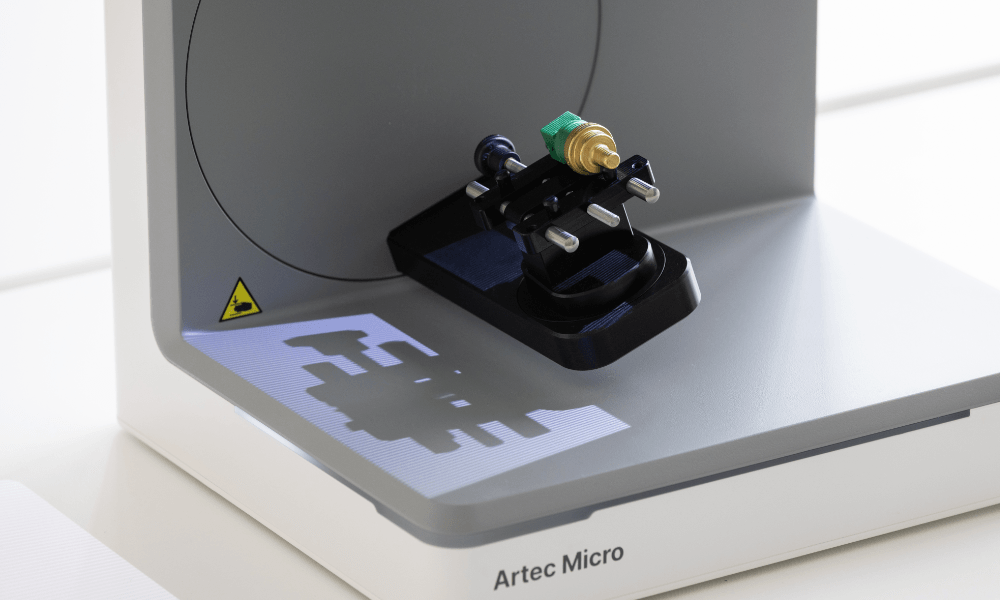

3D scanning in just one click

Optimize your time with a streamlined one-click workflow. Harnessing intelligent algorithms in Artec Studio, the scanner automatically positions your object to follow the ideal scanning trajectory. This guarantees thorough scanning from all angles in a minimal amount of time.

Only a minimum of training is needed with Micro II. Following a quick introduction, you'll be scanning small objects on your own in no time.

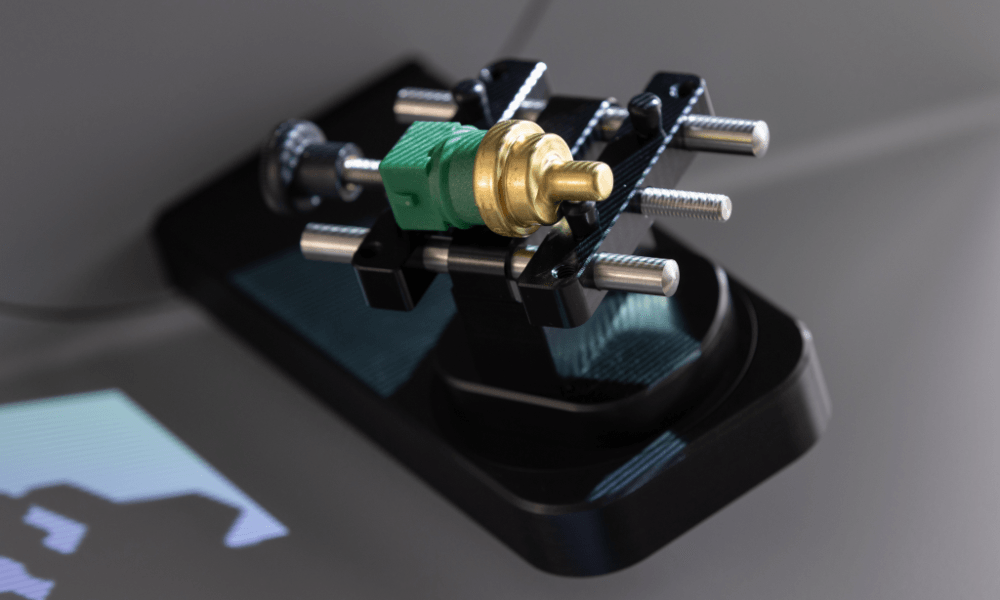

Data capture at lightning speed

Up to 1,000,000 calculations per second

Operating at a rate of 1,000,000 calculations per second, your 3D scanner adeptly captures and processes an impressive 140 million image points every second.

Micro II captures every surface of your object in the least amount of time, using an ideal number of frames. This means minutes and megabytes saved on processing every scan. Now you'll have everything digitized much sooner, and your hard disk will thank you for the extra space saved.

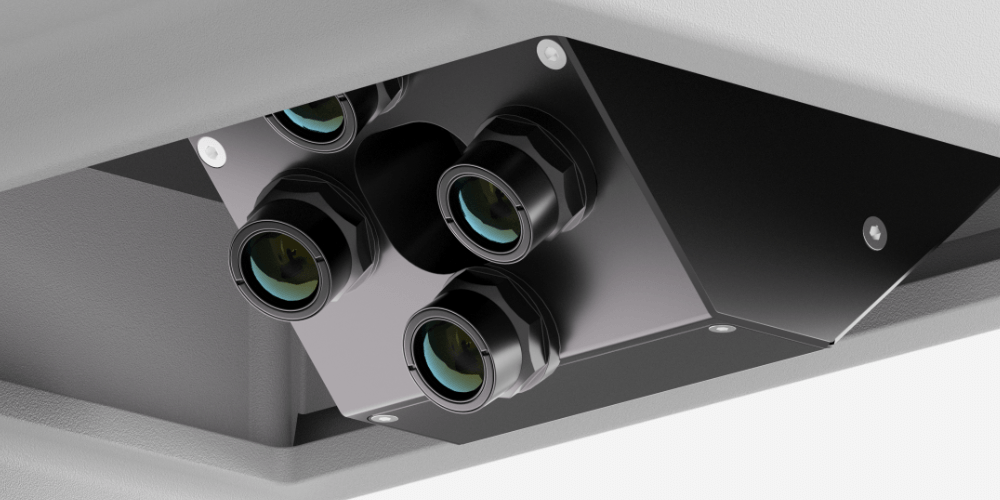

Full coverage for every detail

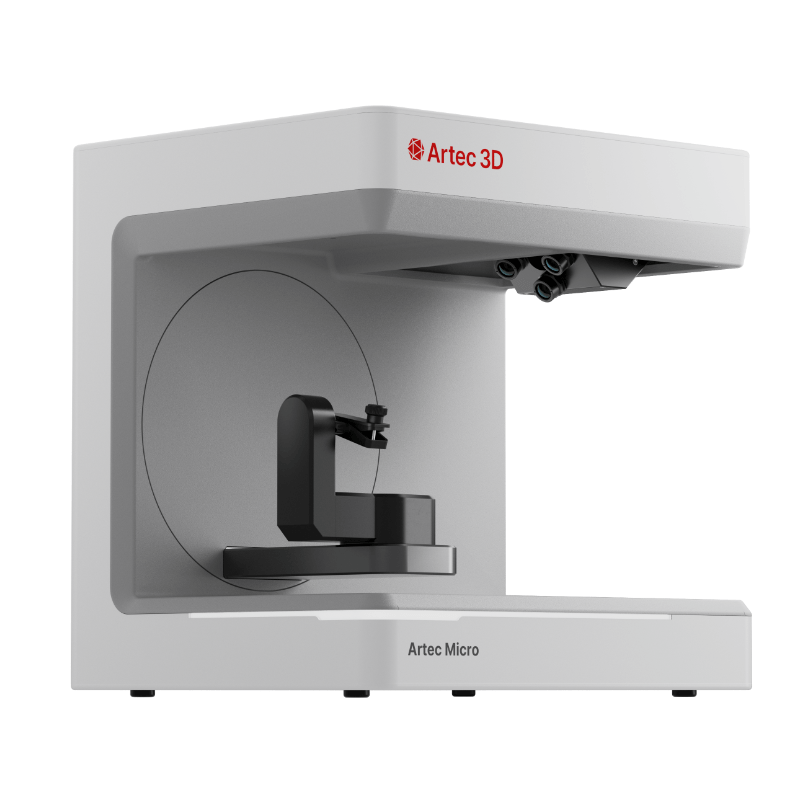

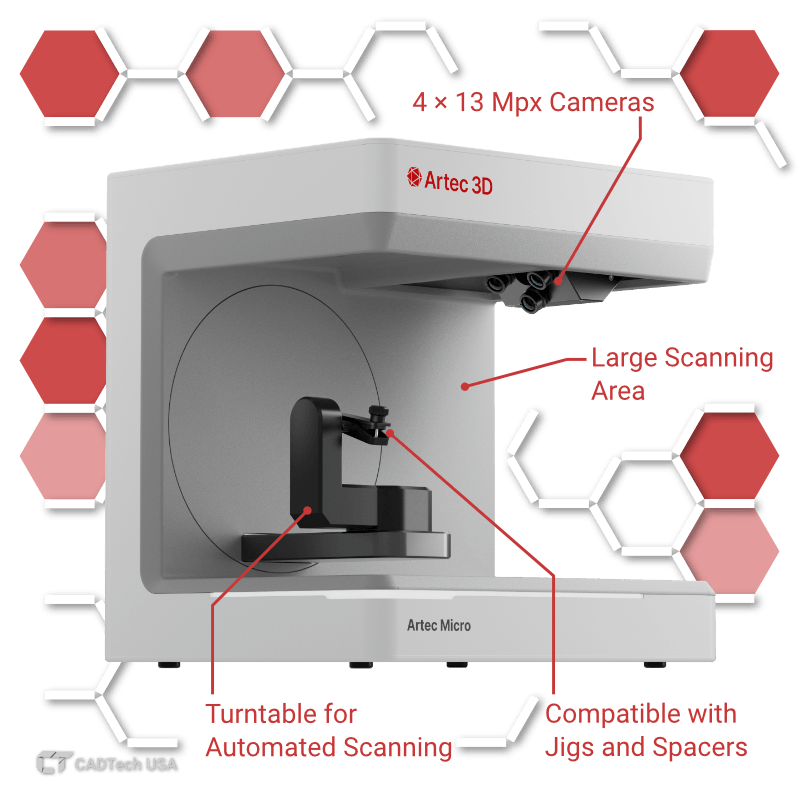

4 × 13 MPX cameras

Fitted with four high-resolution cameras, the Micro II excels in scanning sharp edges and capturing minuscule details – precisely tailored for your needs in 3D scanning small objects.

In addition to the high resolution of the cameras, the unique layout of the four cameras works together to allow the full coverage of all details.

Deep view

Scan deeper with higher-resolution

Delve deeper into the nooks of your object using the scanner's quad-cam scanning technique: four strategically placed 13 MPX cameras designed to capture difficult-to-reach areas, ensuring high-level digitization.

Most 3D scanners can only achieve scanning the surface details, but with the Micro II, hard to reach nooks will be captured effortlessly.

Full color

For hyper-realistic 3D models in full color

Achieve vibrant full-color scans with Micro II. Enhance your 3D models with hyper-realistic color by incorporating high-resolution photos through Artec Studio's photo texturing feature.

Acquiring correct color in 3D scanned objects can be challenging for most scanners, however, the unique high megapixel count of the 4x cameras, combined with the AI processing power of Artec Studio, makes obtaining full color scan possible with a click of a button.

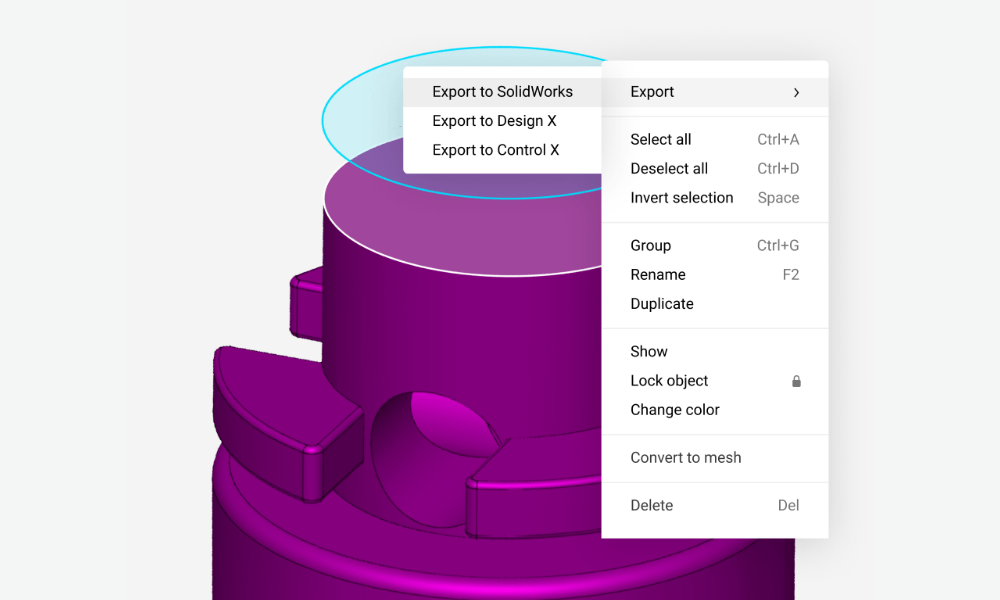

Seamless workflow

Unbeatable with Artec Studio

Artec Studio enhances the already seamless 3D scanning process. After capturing your 3D scan data, effortlessly inspect and engage in reverse engineering directly within AS, or conveniently export for additional reports or inspections.

With Artec Studio’s early upgrades, more features are added every year, which essentially means that your Micro II will also become better and better.

Scan-to-CAD export

Reverse Engineer and Inspect directlt in Artec Studio

Utilize Artec Studio to accurately position and align your scans with CAD primitives, and seamlessly export to SOLIDWORKS or other CAD software. Alternatively, for comprehensive inspections, export directly to Control X to generate in-depth reports.

Simply follow the same series of steps as you would with our handheld scanners, and then export the final 3D model to software such as SOLIDWORKS, PolyWorks Inspector, Control X or Design X.

Quality Inspection

Inspect parts in metrology-grade accuracy

Regardless of your industry, Quality Inspection (QI) is likely a crucial aspect of your workflow. Let Micro II handle the substantial workload when scanning objects for quality control, ensuring exceptional accuracy in every detail you capture.

Delivering metrology-grade scans at up to 5 microns’ accuracy (0.2 thou), not only can Micro “see” well below the human visibility threshold of 40 microns, but its 3D measurements are among the best in today’s cutting-edge scanners, making it a perfect choice for inspection and much more.

Jewelry

Take your custom jewelry art to the next level

Crafting customized jewelry is never an afterthought; it demands meticulous attention to detail where every tiny aspect matters. Micro II simplifies much of the work with just a click, allowing you to redirect your efforts to other tasks in your creative process, saving you hours of time.

Create custom-fitting wedding bands from engagement rings in a matter of hours rather than days. Update family heirlooms by taking an existing diamond or stone and creating an entirely new jewelry piece to perfectly complement it.

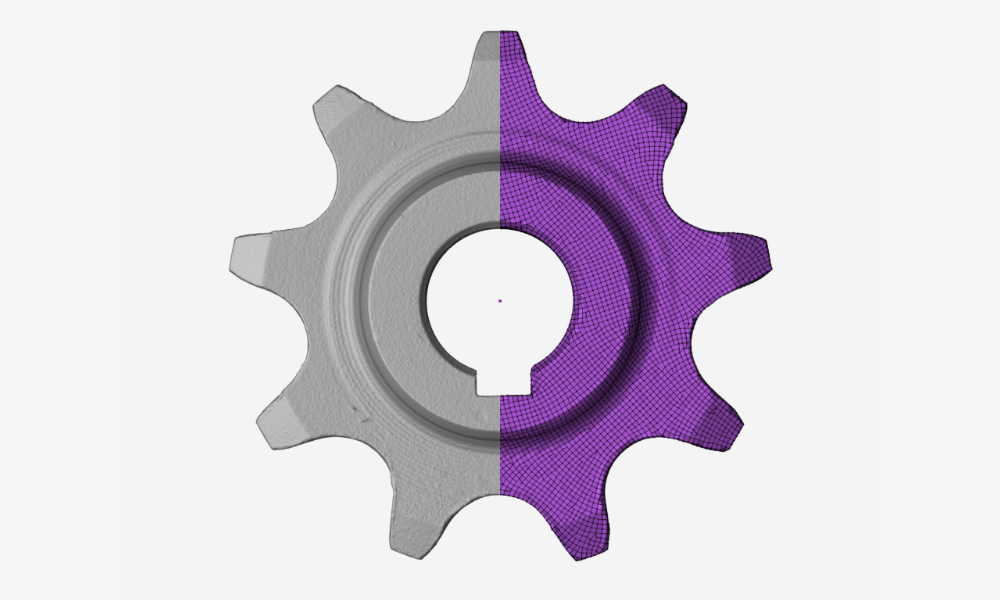

Reverse engineering

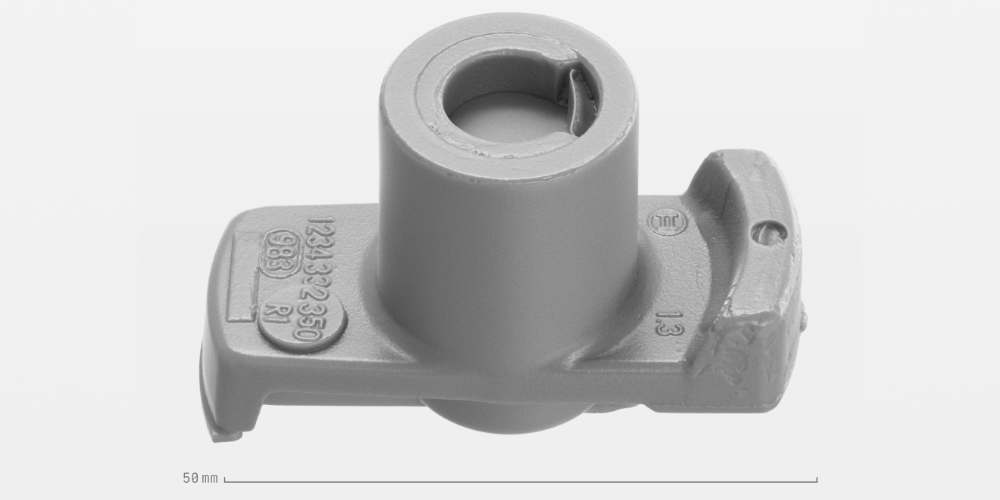

A must have for Scan-to-CAD of small parts

Micro II has you covered when dealing with small or intricate legacy parts lacking ready-made replacements or requiring modifications. Conduct precise reverse engineering directly on your desktop to obtain exactly what you need.

Its precise 3D measurement allows you to digitally fit together legacy parts with those you’re creating, capturing even the finest details that most other scanners will miss. Accelerate your design, prototype, and production cycle by weeks and save thousands in the process.

Forensics

Speed and accuracy for evidence capturing

In crime scene investigations or evidence collection, precision is as critical as efficiency. Micro II allows you to swiftly digitize crucial pieces of evidence, such as bullets or debris for documentation, analysis, or courtroom presentations with speed and accuracy.

Archeology & paleontology

Digitize specific pieces or entire collections in high accuracy

Utilize Micro II to swiftly and effortlessly digitize individual pieces or entire collections with high accuracy and meticulous detail. This process enables you to generate the necessary 3D models for preservation, research, digitization, and restoration purposes.

Design

Digitize designs in high precision

Micro II has you covered, whether you're digitizing your own creations, capturing parts for larger designs, or honing in on fine details. This scanner excels at scanning small objects with lightning speed and unparalleled precision.

Dentistry

One-click 3D capture for dental practices and labs

In applications as meticulous and customizable as dentistry, leave nothing to chance. Micro II is purposefully designed to guarantee that every aspect of your product is precisely tailored to meet your needs, allowing export to ExoCAD and other dental software.

Yes. You can choose the automatic scanning path in the software settings before starting a scan, and let the scanner choose the optimal trajectory and number of frames needed to fully capture the object.

We recommend scanning objects that are up to 200 × 200 × 150 mm and 2 kg (4.4 lb) in size. Examples of objects suitable for scanning with the Micro are engine valves, electrical connectors, watch gears and parts, jewelry, etc.

Artec Micro is the best 3D scanner for reverse engineering, quality control, inspection, dentistry, jewelry, design, and any other area where you need a 3D scanner for small objects with ultra-high accuracy.

Repeatability is a key characteristic for inspection, and the Micro II provides excellent results in this area. While factors such as material and surface finish of the object may slightly affect noise levels, the Micro II generally provides 2-micron repeatability.

The world’s first wireless and AI-driven 3D scanner

| Scanner Type | Handheld, Wireless |

| Object Size 🛈 Typical Object Sizes: M: Engines, Sculptures L: Small boats, Turbines |

M, L |

| Light source | VCSEL + White LED |

| 3D Point Accuracy | Up to 0.10 mm |

| 3D Resolution | Up to 0.20 mm |

| Output Type | 3D mesh + texture |

High accuracy long-range laser 3D scanner, ideal for precise capture of large objects

| Scanner Type | Tripod mounted |

| Object Size 🛈 Typical Object Sizes: L: Small boats, Turbines XL: Warehouse, Airplane |

L, XL |

| Laser source | LiDAR |

| Angular accuracy | 18 arcseconds |

| Range | Up to 130 m |

| Output Type | 3D mesh + texture |